Product Introduction

- Home

- Product Introduction

- Flat Panel Display Production related Equipment

- Flexographic Printer

Flat Panel Display Production related Equipment

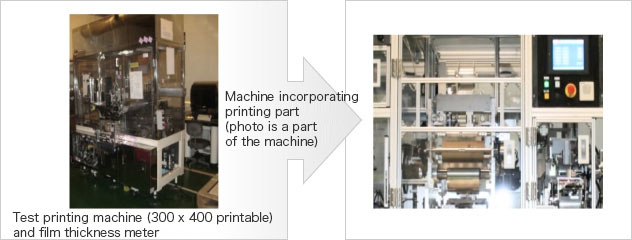

Flexographic Printer High Precision Thin Film Forming Equipment

This equipment forms thin film.

Applying the PI alignemnt film, the insulating film, the adhesive, etc. by flexo printing technique.

Features and Intended Use

| Model | IP series, IN series S series and etc. |

|---|---|

| Intended Use | Printing of alignment film, overcoating and other materials. |

According to the printing conditions, the printing method can be selected.

| IP series | "Perform APR wetting and printing simultaneously." or "Perform printing after APR wetting (separating the APR wetting and the printing)." One of the above can be selected. |

|---|

An example of specifications

| Items | Specifications |

|---|---|

| Printing method | Gravure roll + flexographic printing |

| Printing method size | 100 x 100 to 1100 x 1300mm |

| APR wetting method | Quantitative supply method by anilox roll |

| Drive method | Stage drive |

| Drive transmission method 1: | Direct connection between printing roll gear and printing stage rack gear |

| Drive transmission method 2: | Electrical synchronous operation by servo motor |

| Plate cylinder | Iron based material / plating |

| Runout of plate cylinder | Within 20 µ |

| Relief printing plate (APR plate) | Mechanical fixation |

| Intaglio plate (Anilox) roll | Iron based material / hard Cr plating or ceramic |

| Doctor blade | PET back-up blades SUS420 |

| Ink supply system | Pumping dispenser system |

| Stage | Iron based material, plating, fluorine coating / ceramic |

| Substrate alignment | Auto alignment by image processing or adjustable pin alignment |

| Prebaking | Proxy pin method (Special heat insulating material is used in the pins.) |

Option

Please feel free contact us regarding to the printing pressure, the control method of nip pressure, other driving method and etc.

Others

We have various anilox rolls for testing.

Large-size

Large-size  Small-size

Small-size