Product Introduction

- Home

- Product Introduction

- Flat Panel Display Production related Equipment

- Pressure Sealing Machine

Flat Panel Display Production related Equipment

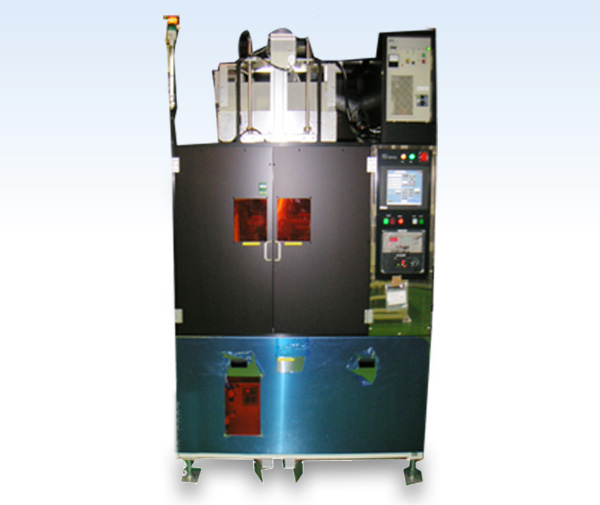

Pressure Sealing Machine

This equipment perform coating the ultraviolet curing resin into the injection hole of LCD after liquid crystal injection, and cure it.

Features and Intended Use

Corresponding to a wide range of specifications, from manual coating by operator to automatic coating by image processing.

| Model | FS series |

|---|---|

| Intended Use | Sealing of liquid crystal injection hole |

An example of specifications

| Items | Specifications |

|---|---|

| Coating method | Automatic coating by dispenser or manual coating by operator |

| Curing method | Ultraviolet (UV) curing |

| UV lamp | Metal halide lamp from 3 kw to 6 kw |

| Processable substrate size | Single plate MAX 15 ", strip (depens on customer's request) |

| Work set | Corresponding to strip shape, single plate shape with special jig |

| Pressurizing method | Substrate pressurization by press unit |

| Pressure control | Pressure control by load cell |

| UV irradiation | Whole surface irradiation by timer control |

| Dispenser unit | XYZ automatic control by AC servo drive (in case of automatic coating) |

| Image processing | Corresponding to coating position detection by image processing |